Modern Cooling System Advancements

CLICK TO VIEW THE ARTICLE HERE!

The engine cooling system

has had its fair share

of nips and tucks over

the last few decades but the

principal behind it is a simple one

and stays the same – keeping

the engine within a certain

temperature range and providing

heating for cabin occupants.

Progress in cooling systems, as with

most vehicle systems these days, is

being pushed by emissions and

efficiency. Several tweaks

to age-old components

have played a part in the

modern vehicle being more

powerful, using less fuel

and having cleaner

emissions than its

predecessors.

We are a long way

from the days of air

cooling and now

seeing computercontrolled

versions

of well-established

cooling components,

including electronically

assisted thermostats,

pulse-width-modulated

fans and electric

water pumps to name

a few. With these

components come new

fault codes and new ways to diagnose cooling systems.

Why are there wires going to the thermostat?

Electronically-assisted thermostats have been around for decades

now and their operating principle is still very much the same

as their earlier, mechanical ancestors. The main drawcards of

electrical control over

the thermostat are

increased power and

improved emissions.

In a perfect world the

optimum combustion

process in a passenger

car occurs at about

110°C. With mechanical

thermostats a middle

ground must be struck

and their rated opening

temperature can open

much lower than 110°C

to allow a ‘buffer’ for

high-load situations.

Electronically assisted

thermostats have the

advantage of being able

to offer a much higher

opening temperature. These thermostats can remain closed as

high as 110°C – at this point they will open unassisted as the wax

pellet melts, just the same as a regular thermostat. This creates

the ideal temperature environment for emissions and efficiency.

The computer uses preset maps and watches several parameters

– including engine load, vehicle and engine speed, coolant and

intake air temperature – to operate the heating element and

quickly open the thermostat further.

This offers a rapid increase in cooling and drops the engine below

110°C.

The lower temperature is ideal for

making power, allowing ignition

timing to be advanced closer to

optimal without increasing knock.

For this reason, the heating element

is most often operated under highload

conditions to increase cooling.

The heating element will also be

operated, even at low load, if the

coolant temperature rises above

113°C to combat overheating.

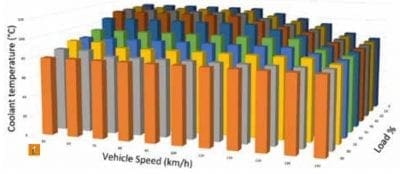

The graph on this page – a

simulated map that controls the

thermostat heating element – shows

what the computer is thinking (pic 1).

The coolant temperature is lowered

as vehicle load and

speed increases.

Check its pulse!

From belt-driven

fans to low/high

staged relays, we

now commonly see

vehicles with pulsewidth-modulated

cooling fans. Pulse

width modulation ticks

all the efficiency and

NVH (noise, vibrations,

harshness) boxes for

manufacturers.

The benefits of precise fan-speed control are obvious but often

the speed range is not infinite. It is quite common to have preset

stages of fan operation, loosely evidenced by only a handful

of speeds being available when bi-directionally controlling fans

through a scan tool. Understand that engineers have worked

long and hard to perfect these speed stages to provide a balance

between effective cooling, energy efficiency and driver comfort.

Under certain conditions

a 64 per cent duty cycle

may be ideal for cooling

but 61 per cent may be

a better option due to

the noise and vibration

of a particular fan

assembly.

With a 10.61 per

cent duty cycle (blue)

commanded by the

computer, this small

cooling fan draws only

300 milliamps (red)

(pic 2).

For testing purposes,

if no scan tool bidirectional

tests are

available, the old theory of increasing load to get the fans on high

still holds true, so set the a/c to max and turn on as many loads

as possible.

With a rise in commanded duty cycle to 38.55 per cent (blue), fan

current increases to 814 milliamps (red) (pic 3).

Go with the flow

The theory for going electric with water pumps seems logical –

old mechanical-driven pumps, after all, rob precious power and

economy.

1

2

by Brendan Sorensen

The forecast is

hot for cooling

systems

The Automotive Technician 9

Critical thinkers might

argue that you cannot

create or destroy

energy, so isn’t this

just putting more load

on the belt-driven

alternator to provide

power for an electric

pump?

Well, there’s a little

more to it than that.

Mechanical water

pumps are directly

linked to engine speed,

so often pump more

coolant than is needed.

Conversely, sometimes

more coolant flow

would be ideal, such as during engine shut-off after hard driving.

The main benefit of an electric water pump comes from its

variable nature. Pulse width modulation allows the computer to

tailor fit the coolant flow to your engine’s current situation, and as

sparingly as possible. Electrification also provides several side

benefits, such as the reduced complexity of belt/chain designs

and the ability to remotely mount the pump in unused space.

Expect to see more of these modern water pumps because they

are ideal for hybrid and electric vehicles, which don’t have the

luxury of a constantly spinning mechanical engine.

Where to from here?

If you think we’ve made progress in cooling systems, grab an iced

tea because the future is hot.

The latest semi-conductors

used in hybrid and electric

vehicles produce a heat

flux measurement of

400W/cm², comparable to

the surface of the sun!

Huge cooling requirements

will be demanded from

stationary vehicles and

SAE J1772 electric-vehicle

connector standards

allow for up to 240kW of

charging power.

The sensitivity of

electronics creates the

need for very precise

and component-specific

cooling and this is where

glycol-coolant-based cooling systems show their age. Complex

systems with handfuls of small passages become hard to bleed

and regulate. The various metal components that require cooling

create bi-metal corrosion issues.

We are starting to see new solutions. The BMW i3 is an electric

vehicle that uses the existing a/c system to cool the battery pack

through refrigerant tubes mounted in a cooling plate, which acts a

heat sink.

But while the technology is changing the customer complaints will

remain the same. When Mrs Jones complains that her feet are

cold on morning drives, the keen technician will complement their

old-school physical tests and inspection with the interrogation of

data from all modules.

The poorly trained will quote a pair of slippers.