CLICK HERE TO VIEW THE PDF MAGAZINE ARTICLE WITH IMAGES

Brendan’s latest article in The Automotive Technician national trade magazine is a great example of why paying some labour time to carry out evidence-based testing to get to the root cause of your problem is our preferred diagnostic method and ends up cheaper in the long-run. We hate seeing cars who have suffered guess-nostics or swap-nostics elsewhere, with unnecessary replacement parts on modern vehicles often costing well more than thorough testing would have if the time was taken initially.

This edition I will run through a recent case study from my shop, with a couple wrong turns as the diagnostic path is not always as straightforward as some case studies would have you believe.

This highly modified, Supercharged V8 VEII Commodore was a trade job for a performance shop. It went through a large build with them around 6 months ago and since then had gone in and out of different periods of perfect running 1000+hp track days, dead misfires, fuel cut type symptoms and for good measure, a new flywheel and bellhousing from an exploded clutch.

Throughout these changing symptoms also came an extensive list of parts they (and sometimes the owner) had replaced including leads, aftermarket coils, genuine coils, injectors and even donor ignition coil wiring looms (short loom from each coil to the main junction connector for that banks coil wires). Tests they had completed were also quite in-depth – compression testing, valve spring visual inspection, fuel pressure, injector bench testing, dyno datalogging – certainly not 2-minute jobs.

The vehicle presented to me with a repeatable mid to high load driveability problem. It could idle perfectly, free-rev no problem at standstill, and push you back in your seat under 20% throttle on the road, but as soon as you pushed any higher in the load range it surged, knocked, misfired, backfired and hesitated terribly. I was happy it was repeatable; I wasn’t so happy about how difficult it is to test a 1000hp car on the street at higher loads and each time waiting for the possibility of it really going BANG during my datalogging pulls.

I started with my Snap On Solus, which is my favourite scantool for datalogging for deep analysis later on the PC. Midway into the WOT pull, around 3500rpm, I dropped a cursor at the point the engine rpm started to faulter (the point it started faulting), and clear as day I could see immediately B1S1 sharply dropped lean, while B2S1 remained rich as it should on a WOT pull PIC 1. So, it seems likely the fault relates to Bank 1.

Taking the first wrong turn, I also couldn’t help but notice the low side fuel pressure (this system has a low-side fuel pressure sensor) was dropping during the pull, starting around 35kpa and dropping to 32kpa during the fault – I’m no LS engine expert but that sounded terribly low to me. I pulled up some standard LS engine specs and sure enough this was terribly low. Here’s where everyone finds out I’m more comfortable around Camry’s than Corvettes – I spoke to the performance shop and they assured me for this highly modified fuel system it is achieving the correct target numbers for the tune. The system consists of dual stage fuel pumps, so just to satisfy myself I bypassed the boost pressure activated 2nd stage pump control by manually activating the relays and running both pumps constantly, which gave no change in symptom.

With no other data PID’S giving any further clear direction, no fault codes and even all misfire monitors reading 0 when it clearly had some terrible misfires when faulting (perhaps this is something the tuner had edited) it was time to move on from the scantool, to some more hands on non-intrusive testing.

With 4 scope channels at my disposal (Santa didn’t bring me an 8-channel Pico), I needed to gather as much data as possible on each short test run. A good place to start on petrol driveability is monitoring cam, crank, coils and injectors. Any intermittent test equipment poor connection would not be acceptable, so for any voltage readings on these high vibration test drives I used my Pomona wire piercers over my more favourable back probing pins which might wriggle out under vibration. The crank sensor was buried, so for now I made a voltage connection on the accessible cam sensor (blue). Consulting the wiring diagram showed me the coils and injectors for each bank all run through their own bank specific fuse – so with one fuse buddy and one current clamp I was able to see all Bank 1 coil and injection current events on one channel (yellow). For this first test I used my two remaining channels to connect into the control wire of Cylinder 1 coil (red) and injector (green).

Pic 2 Shows perfect running at idle, with the large yellow coil ramps being the coils and the smaller yellow coil ramps being the injectors on bank 1. Roll on the load down the road and it bucked and kicked as repeatably as ever and the waveforms gathered were astonishing Pic 3.

Coil control remained steady, however there were clearly some missing coil current ramps when there was good control. Injection control was chaotic, some good longer duration high load injections, some missing injection controls, and even some random, non-rhythmic multiple injections on the same cylinder.

In hindsight now, the steady coil control should have led me elsewhere, but intrigued I let the car cool overnight and returned to waste half an hour making solid connection on the crank sensor, only to find my cam and crank sensors reported steadily throughout the fault.

After a cup of coffee mulling over some wiring diagrams, I focussed on a Haynes Pro earth point location diagram. Engine running, I ensured all earth points in the engine bay had no excessive voltage drop by measuring between it and battery earth, all giving a good reading under 50mv. Those that I couldn’t physically access the ground lug, I tested at the wiring loom connectors further up the circuit where more accessible. To up the ante, engine running I also used my high current test light – a H4 headlight with low and high beam bridged to give a decent 10amp current draw, to ensure all earth points in the engine bay could light my bulb brightly.

Engine off, while I had it out, I also used the H4 test light to confirm my coil power and earth, and injector power could also light the bulb brightly. Here’s your first hint – content with the bright bulb, I skipped carrying out voltage drop testing with my multimeter on these circuits, could this have changed my path?

Running over the facts so far with the guys in the shop, there is always one who says those all too familiar words – maybe it’s the ECU. It didn’t sit right with me – such a load dependant fault, able to function logically at other loads, when you think of the ECU on a circuit board level it’s not the way an ECU fails. Couldn’t hurt to check though, so I wasted another hour or so digging the ECU out to brightly light my H4 bulb on all the power and ground supply circuits on the unplugged ECU connector.

I remembered the scope capture showing a coil control event with no current ramp – that seemed like the lowest hanging fruit to chase at this point, particularly given the list of previous ignition system component replacements that apparently gave temporary relief to whatever symptom it had that chosen month. Remembering my oxygen sensors were alluding to the fault being on bank 1, I wanted to see if anything was different between a coil on bank 1 and bank 2, since on this engine each bank has its own circuit, basically a known good to compare.

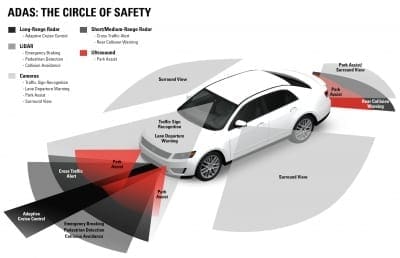

The four wire coils on this GM engine are a little different to others PIC 4. Left to right they have a power (D), a 5v transistor trigger (C), a dedicated transistor earth wire (B) – running a wire all the way back to the ECU to give a filtered ground, much like a sensor ground does – and a coil ground (A) – to carry the hefty 10amps or so of actual coil current. 3 of the wires are shared by all coils on its respective bank, aside from Pin C, the 5v transistor trigger which is individual to each coil to fire at the correct time.

Not exactly sure what I was looking for, or what I might find, I made voltage connections into Pin B on a bank 2 coil (bank 2 shared transistor earth) (Channel A), a bank 2 coil trigger (Channel B), Pin B on a bank 1 coil (bank 1 shared transistor earth) (Channel C), and this time monitoring bank 2 coil and injector current for any abnormality with an amp clamp at its fuse, to confirm if the fault truly was only on bank 1 (Channel D).

Focussing on Channel A (Blue) and Channel C (Green), there was not much activity on each bank’s transistor earth during idle and low load. However, during the fault, large peaks started to form, particularly on the bank 1 shared transistor earth, with some of the voltage drops (deviation from true earth 0V) rising to over 600mv PIC5. Such is the duration and shape of these voltage drop ramps on the green trace, they could be mistaken for coil current ramps if you hadn’t been told what you were looking at. While activity increased on the bank 2 transistor earth during the fault, the ramps it displayed were predominantly mini versions of what was happening on bank 1 during bank 1 coil events – I would suggest these are actually bank 1 fault events that are making their way electrically onto the bank 2 circuit.

Multiple facts so far pointed to something being amiss on this bank 1 coil circuit. I thought it through while the car cooled itself and I did a brake job to cool my mind. I had good coil control, I had tested the power and the ground with a 10-amp test light – BUT, I had not tested them flying down the road during the fault, with heat, vibration and movement. My thoughts turned to ground point 4, the bank 1 coil main ground, bolted to the rear of the cylinder head, inaccessible so I had proved it could flow 10amps up at the bank 1 main wiring connector. I hooked the same test light up to this pin again, then shook as much loom as I could reach – and the light dulled!

With great direction, I used a borescope to follow the loom down behind the engine, and bullseye, out of the thick wiring loom at this point exited one single inch long wire, with an exposed wire end, resting on an empty thread in the head where a crimped earth lug should obviously be. The wire was making a decent earth connection at idle, but when 1000 horses try to rip the motor off its mounts, the connection is compromised.

I’d love to say I could explain the knock-on effects of this poor coil earth, but my knowledge only extends so far to say it looks like the current went looking for a different path, finding its way into the coil transistor earth, causing the large voltage drops as the tiny wire struggled to deal with far more current than it was intended. The odd extra injections also raise some questions – is the ECU using this transistor earth wire in a Toyota IGF style monitoring, and could it possibly have some contribution into injection timing, surely not?

In hindsight, I would have loved to have spent some more time gathering ‘money shot’s’ like what would have been an extreme voltage drop on the bank 1 coil main earth during the fault, but I had all I needed to take this job to the bank. With a back probe in the accessible bank 1 harness connector main coil earth pin, I ran a jumper wire and alligator clip to the engine block. Rolling on the throttle, for the first time I felt the full output of this engine, which prompted a passing pedestrian to I assume ruin his undies as he mimed what must have been a plunger on his forehead as I saw him disappear quickly in my rear-view mirror yelling something along the lines of ‘Banker!’