Battery registration and programing

VIEW THE MAGAZINE ARTICLE HERE

Text only version (magazine version above)-

Recently, I had the pleasure of inviting some fellow TAT subscribers into my workshop for a ‘playday’ and the topic of battery registration came up.

For over 15 years now, European marques have strictly instructed the process to be carried out via a suitable scan tool at every battery replacement. With the procedure becoming common place in even the cheapest of modern econo-boxes, I thought it was high time to get to the bottom of what the process does, and the hotly debated question – is it necessary?

Lead-Acid Battery

Improving on the regular old flooded cell batteries, which required regular water top up, advancements were initially made by replacing the average 6% antimony used to strengthen lead plates, with familiar sounding materials such as calcium or silver. These were first referred to as “maintenance free” batteries.

With benefits like reduced outgassing, corrosion and self-discharge, these batteries prefer a higher charge rate than traditional, around 14.4 – 14.8V, to reach full capacity.

The Achilles heel of calcium batteries is their intense dislike of deep cycle discharge, more so even than traditional flooded cells.

(Pic 1 – Ford Intelligent Battery Sensor – Mounted on the negative battery terminal, the Ford Intelligent Battery Sensor precisely measures voltage, current and temperature)

Still in the lead acid battery family, a unit enjoying rapid growth due to the harsh environment of ‘Start-Stop’ equipped vehicles is the Absorbed Glass Mat (AGM) battery – also referred to as Valve-Regulated Lead Acid (VRLA), or a lead battery with a pressure relief valve.

The earlier flooded type batteries are simply not robust enough for ‘Start-Stop’ and repeated cycling causes a sharp capacity fade after only two years of use.

With AGM technology, the sulfuric acid is absorbed by a very fine fiberglass mat, making the battery spill-proof. Compared to flooded cell batteries, AGM has very low internal resistance, can charge 5 times faster, is capable to deliver high current on demand and offers a relatively long service life, even when deep cycled.

Unfortunately, AGM batteries are sensitive to overcharging. A burst charge of 14.4V (and higher) is OK; however, the float charge should be reduced to around 13.5V (northern state temperatures may require lower). Regular charging systems for flooded lead-acid often have a fixed float voltage setting of 14.40V; a direct replacement with an AGM unit could overcharge the battery on long drives.

AGM and other ‘sealed’ batteries (such as Gel) do not like heat and should be installed away from the engine compartment. Manufacturers recommend halting charge if the battery core reaches 49°C. High charge rates and high heat results in outgassing (overpowering the pressure relief valve) which will dry out and kill the battery.

Registration vs Programming

Although battery registration is utilised by many brands now, I will speak mainly of BMW, who have been doing it for well over a decade. There are generally two service options, Battery Registration and Battery Programming/Coding.

(Pic 2 – G Scan Battery Register – Both factory and many aftermarket scan tools have battery registration capabilities)

Every time a battery is replaced, using a suitable scan tool, the service function ‘Register battery replacement’ should be run. This completes the following operations:

- Stored battery statistics (battery charge level, current, voltage, temperature) are deleted

- Battery capacity is set to 80%

- Current Odometer reading is stored along with readings of previous battery replacements.

This registration function is advised when carrying out a professional battery installation, and certainly many vehicles will not clear cluster warning messages and low voltage/battery fault codes until it has been completed.

BMW Technical Training – “If the battery change is not registered, the power management will not function properly, with the result that Check Control messages may be displayed and functions limited by individual electrical consumers being switched off or having their power consumption reduced.”

I always recommend to carry out, and charge the customer for this process – however, in real world terms, my research suggests there is no evidence behind rumored alternator and electrical damage from not registering batteries. With the dynamic nature of the ‘smart charging’ systems, when fitting an identical new battery, the system is quite capable of adapting its strategy to the ‘mysterious’ new battery. Any charging adjustments based on age would be in millivolts, effecting long-term battery life negligibly.

Indeed, once a weak battery has been detected, many systems will not retract error messages/not operate some systems until battery registration is completed.

Battery Programming

The second, and I believe most important, aspect of this topic is Battery Programming or Coding.

If a different battery has been fitted, it is imperative that the car knows the specs of this new battery to modify its entire charging algorithm.

An example –

A 2006 BMW 330i E90 model provides the following choices when programming a battery in:

90Ah AGM, 90Ah, 80Ah AGM, 80Ah, 70Ah AGM, 70Ah, 55Ah, 46Ah.

Suppose our high spec model came with, and is programmed for a 90Ah AGM battery, but the customer wants to save money by fitting a 55Ah lead/calcium battery. Aside from the real capacity issues, we know that the car is going to use an AGM based charging strategy which is terrible for a lead/calcium. On the flip side, perhaps a customer is doing less driving now and an upgrade to an AGM better suited to the down time is preferable. The charge strategy needs to know this to avoid overcharging. Both situations will result in drastically reduced battery life if not programmed in properly.

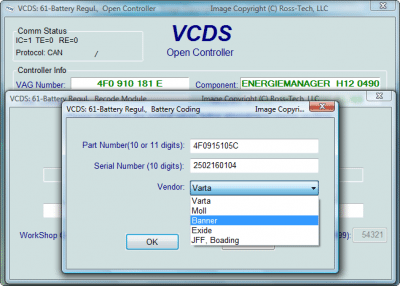

Where makes like VW call for a specific code to be entered – if your physically correct aftermarket battery does not have a manufacturer recognised code printed on it, your best bet is to match up and enter a code with the same chemistry and specs as the battery you are installing – this is of course not ideal though.

(Pic 3 – Ross Tech Battery Coding – Although physically capable, many Australian sold batteries are not available for selection when coding in a new battery.)

(Pic 4– VW Battery Code – For VW, the 10 digit serial number is often preceded by the battery vendor code VA0, making the 10 digit serial number on this battery 360315F0B7.)

If a battery is staying with the same chemistry, but the Ah rating is changing, although I always recommend to reprogram the correct rating in, physically going up in Ah – ‘capacity’ – should be a non-issue. If the system wants to maintain the battery at about 80% State Of Charge (SOC), and then put energy in, the result will be that when it puts energy in, there is more capacity to put even more in. If a smaller battery was installed, the logic should still cut out based upon SOC, but the conditions may be such that it causes overcharge conditions or puts too much energy in too quick.

Australian Specific

Many Australian batteries will not provide an Ah rating but instead a Reserve Capacity (RC). Although they are separate measurements, they are very similar in nature and there are many handy formula for calculating the Ah to be coded for your replacement battery. I find the easiest to be:

RC/2.4=Ah

Of course having the right tool and battery for the job is always going to be best, but in a pinch (which can often happen in this wide and wonderful country of ours) the main things to remember are –

- The battery being installed must be the same chemistry that is programmed into the vehicle.

- Install a battery as close to the programmed Ah rating as possible – physically going up in capacity if forced.

Reference table –

- CCA (Cold Cranking Amps)

Represents the amperage capacity a fully charged battery can deliver @ -18°C for 30

seconds before the voltage of the battery falls below 7.2 volts.

- Ah (Ampere hour)

Derived from discharging a fully charged battery at a constant amp draw without the voltage of the battery falling below 10.5 volts.

The constant amp draw is multiplied by the length of the test to come up with the Amp

Hour Rating.

- RC (Reserve Capacity)

Reserve capacity is expressed in minutes and relates to the amount of time a fully

charged battery can maintain a constant draw of 25 amps @ 27°C before the voltage

falls below 10.5 volts.

- State of Charge (SOC)

A percentage estimate of how full the battery is.

- Sulfate

Deposits formed on the plates of the battery as the electrolyte gives up its sulfuric

acid. Excessive deep cycling of a battery can cause a hardening of this deposit and make it impossible to return sulfate to the electrolyte. A sulfated battery is one which has these hardened deposits on the plates and cannot be recharged to full capacity.