Diesel Hybrid Exhaust Gas Recirculation (EGR) Systems

Hybrid EGR – View the Magazine PDF File Here

Diesel Hybrid Exhaust Gas Recirculation Systems

Whichever side of the fence you’re on, it is clear that emissions is an increasingly dirty word, and internal combustion engines have the finger squarely pointed at them by lawmakers.

Near the top of the hit list is diesel (thanks VW Dieselgate). With a modern diesel engine still relatively simple in design, it is the emissions management and after treatment systems bolted onto it that can resemble something from the Mars rover.

One such system, perhaps with the worst rap sheet of them all, is Exhaust Gas Recirculation (EGR), or as many forum goers will correct you, ‘The Antiperformance Valve’. A valve with such bad intentions it has entire online shops dedicated to banishing it from existence with blanking plates and voltage modifiers.

Heck it’s got such a bad reputation there’s even old wives tales about it.

“Want the best bang for buck, get the blanking plate with a hole drilled in it” boasted Jim to Rob down the pub one Sunday, not knowing his mate Tom actually told him to drill a hole in the intake air throttle flap. Tom knew on some models this could fool the computer into not cottoning on to the fact that air pressure and flow were not as it modelled when EGR was commanded, stopping that ‘annoying’ emissions light coming on.

Banter aside, the once primitive EGR system has gone through changes, and leads the way as one of the cheapest and most effective ways of reducing Nitrogen Oxide emissions.

This is good for anyone with a vested interest in diesel, because it is my belief that expensive after treatment systems will be what ultimately forces the market away from diesel. The after treatment list grows by the day, with even the lowest of base models utilising expensive items such as the Diesel Oxidisation Catalyst (DOC), NOx Storage Catalyst (NSC), Diesel Particulate Filter (DPF) and Selective Catalytic Reduction (SCR, in layman’s terms – Exhaust fluid injection).

So how is our soot depositing, intake blocking, code setting enemy, EGR, improving to help keep diesel purchase reasonably priced for consumers?

EGR Advancements

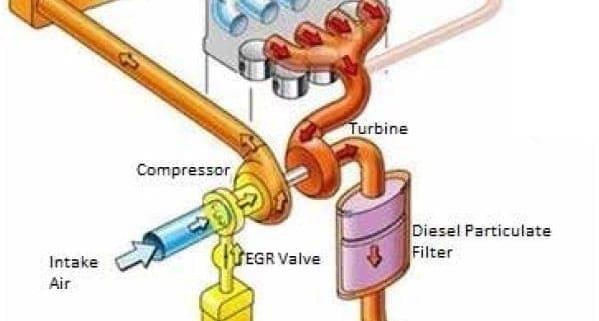

The regular EGR system we are all used to, is commonly referred to as High Pressure EGR (HP EGR), or sometimes referred to as Short Route EGR. This utilises exhaust gas in the exhaust manifold, before the turbine, routed into the intake manifold, after the turbo compressor.

Increasingly becoming the norm, are systems referred to as Hybrid EGR. These keep the benefits of High Pressure EGR, as well as adding in a Low Pressure EGR (LP EGR) system, sometimes referred to as Long Route EGR.

Low pressure EGR takes exhaust gas from further downstream of the turbine, often after a DPF, routing it into the intake stream, before the turbo compressor. Each system, HP EGR and LP EGR, has different pros and cons, hence each is operated during different load situations in a Hybrid EGR system, sometimes even with both operating at the same time.

| Advantages | Drawback | |

| High Pressure EGR | · Fast EGR response time

· Turbo compressor efficiency and durability |

· Unstable EGR cylinder distribution

· Soot deposits through system · Hotter EGR · Reduce turbine wheel response |

| Low Pressure EGR | · Equal EGR cylinder distribution

· Clean EGR (after DPF) · Highly cooled EGR · Improved turbine wheel response |

· Slow EGR response time

· Turbo compressor efficiency and durability · Increased compressor size |

Let’s take a look at these points a little closer –

Response time

Best thought of as ‘EGR lag’. HP EGR can have a valve mounted directly on the intake manifold, so when it opens, exhaust gas reaches the cylinders quickly. LP EGR requires exhaust gas to travel the entire length of intake plumbing before its result is achieved. This long path does however improve equal cylinder distribution in the LP EGR system.

Soot Deposits

As LP EGR can use exhaust gas after the DPF, it is close to being soot free. This gas does need to pass through the turbo compressor, so often for safety a filter will be incorporated in the LP EGR cooler to eliminate any possible soot particles. This is something to consider when purchasing aftermarket coolers.

Turbo compressor efficiency

LP EGR allows all exhaust gas to travel through the turbine, allowing quicker turbo response than a HP EGR system which bleeds precious exhaust energy before the turbine. Conversely, in a LP EGR system we now have fresh air and exhaust gas passing through the turbo inlet compressor, meaning a larger turbo is required to handle this larger amount of gas.

This larger amount of gas flow in LP EGR is particularly useful at low speed, high and low load points, where traditionally EGR rates are high but overall air flow is low. The operating point of the Variable Nozzle Turbo can be moved to an area of higher efficiency, increasing fuel economy and decreasing compressor surge while decreasing NOx and soot.

In high speed, high load points, HP EGR gradually decreases the difference between exhaust and intake pressures, even lower than LP EGR, so HP EGR becomes the better option for the trade-off relationship between fuel economy, NOx and soot.

Throughout the midrange and steady states, a combination of HP EGR and LP EGR can be used.

Turbo compressor durability

With the turbo compressor wheel living most of its life well over 100,000 rpm, routing exhaust gas through it is a tricky proposition. Particular attention is paid to the EGR cooler in a LP EGR system, as any water droplets formed from condensation as the hot exhaust gas pass through the cooler could be disastrous. Often an EGR cooler bypass valve will be utilised to prevent hot exhaust gas passing through a dead cold cooler as the vehicle warms up.

Exhaust gas can also accelerate corrosion on the compressor wheel, therefore a special turbo designed to resist this must be used.

Both LP and HP EGR systems require forms of throttling air to create pressure differential, for the exhaust gas to find its way back into the intake stream –

- Variable Nozzle Turbo (VNT) – The variables nozzles of the turbo are a key aspect in manipulating exhaust backpressure throughout the load range. It is able to create higher exhaust manifold pressure than intake pressure, allowing exhaust gas to flow into the intake manifold.

- Intake air throttle valve – When load situations mean it is not reasonable to use just the VNT to create high exhaust pressure, this valve reduces the intake manifold opening, reducing intake manifold pressure, allowing exhaust gas to flow into the intake manifold. A secondary function of this valve is the closing on engine shut down for smoothness and to prevent an emergency diesel runaway situation.

- Exhaust air throttle valve – Usually located downstream of the DPF, this is the preferred method of creating exhaust backpressure in a LP EGR system to drive exhaust gas into the intake piping.

Less common in current passenger vehicles –

- EGR pump – A less fuel efficient option on a LP EGR system is using an EGR pump, downstream of the DPF, either electrically or crankshaft driven, to pump EGR gas towards the intake.

- Turbo compounding – Common in trucking, a separate turbine is added after the turbocharger’s turbine. This increases EGR flow by increasing exhaust backpressure. To recover some of this energy lost through pumping losses, the added turbine transmits to the crankshaft through a transmission.

- Reed valve (one-way valve) – As exhaust pulses come in peaks and valleys, the use of a reed valve can allow exhaust gas to flow into the intake during a peak, even though the average exhaust pressure is below intake pressure, which would otherwise to be too low to drive flow.

- Fast rotating valves – Mahle has developed a component named – Rotating fast-switching charge air valve (SLV-R). Similar in concept to a reed valve, this is best thought of as an electrically powered whirly bird, installed in the intake stream, creating intake air pressure peaks and valleys as it continually spins.

As you can see, great effort is used to get exhaust gas back into the intake, so as ‘EGR Performance’, ‘EGR Flow’ and ‘NOx level exceeded’ codes become more and more common it is important to consider the whole system and how it works in unity rather than focusing on the actual EGR valve itself.

The Engine Control Module, is often watching Mass Air Flow (MAF) and Manifold Absolute Pressure (MAP) sensor readings to set these fault codes, particularly in systems that do not utilise a position sensor on the EGR valve. Obtaining the correct manufacturer code setting parameters can be the key to faster diagnosis.

I find TaT’s ‘Good scan/scope data’ section (accessed from the TaT homepage) a great resource when diagnosing EGR flow problems. I’ll often jot out a table of RPM, MAF, and EGR command to compare my problem vehicle with known good readings. This gives great direction for possible system blockages, so you can recommend physical pull apart of the system to the customer with confidence.

Be forewarned though with this method to ensure all other parameters are equal when making your table. As I hope I’ve demonstrated, modern EGR command is a complex dance between engine temperature, load, HP EGR and LP EGR systems – so you want to ensure you are comparing apples with apples.